How Does a Fine Art Inkjet Printer Work? By Tim Jones

Sometimes, when printing, you might find yourself thinking about how the printer actually works. For instance, how can it fire the ink onto the paper and print our images? In this blog, we dissect how an inkjet printer works, and how it actually manages to print your favourite photographs.

How Does the Print Head Work?

If you have ever looked at the underneath print head, you might have seen a row or strips of what looks like a gold-like material – these are the printer nozzles. They are normally around a 1/10th of a human hair in width around 10 micrometres. The head contains 100s of nozzles for each colour and projects the ink at around 10 metres per second. So, what does this all mean for our prints?

It allows us to get a smooth appearance to our prints with very little dot gain. Dot gain is where we will be able to see the dot of ink on the page. This can generally be controlled by the DPI setting on the printer. A good setting to have is 1200 DPI or above, as it can be argued that the human eye can’t see past 1200-1440 DPI. But, the best thing to do is try out your own tests and judge for yourself.

The ink is projected from the nozzle by the use of a pulse of pressure, this pushes the ink through the nozzle onto the page. There are two types of methods that are used to create the pulses – the thermal bubble process and the piezoelectric process.

Thermal bubble process

|

The Thermal bubble process is mainly used with Canon printers like the Pro-300 and Pro-1000. The process involves heating a very thin heat resistor in which an electrical current is passed. This heats the ink to boiling point, creating a bubble of ink. The creation of this bubble forms a pressure within the nozzle which, in turn, forces the ink out of the nozzle onto the page. This whole process takes less than one microsecond. After the ink has been forced out, the ink bubble cools down and contracts which draws more ink into the nozzle priming the nozzle for the next pulse of ink. |

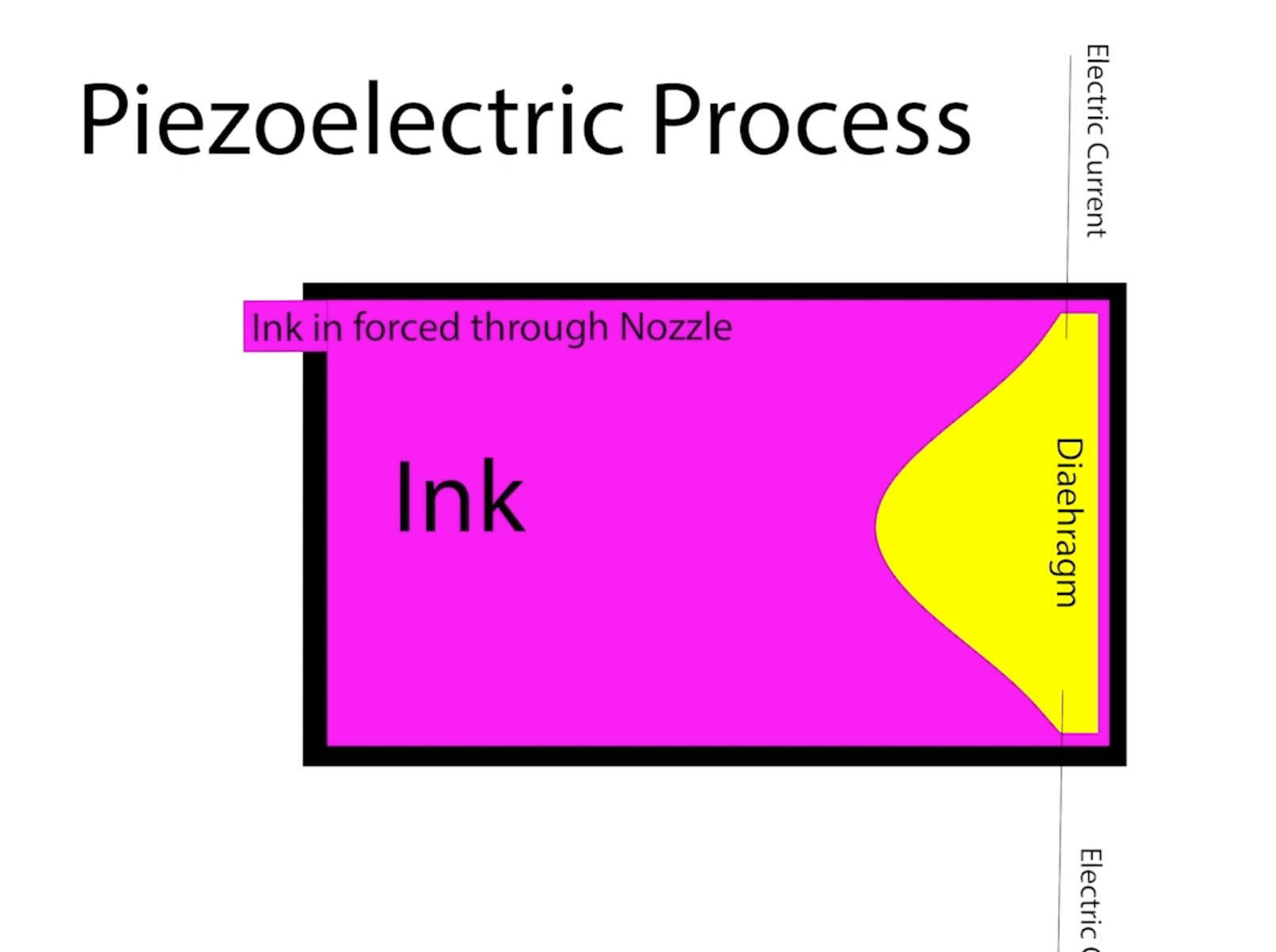

Piezoelectric Process

| Another way to create this pulse needed to fire the ink onto the page is to use the piezoelectric process. Piezoelectric is used and patented by Epson. In very simple terms, this process works by passing an electric current through a piezo crystal which acts almost like a diaphragm, flexing and squeezing the ink out of the nozzle. When the piezo crystal contracts, it draws new ink into the head ready for use on the next pass of the head. This process, like the thermal process, happens within less than 1 microsecond. |  |

Another way to create this pulse needed to fire the ink onto the page is to use the piezoelectric process. Piezoelectric is used and patented by Epson. In very simple terms, this process works by passing an electric current through a piezo crystal which acts almost like a diaphragm, flexing and squeezing the ink out of the nozzle. When the piezo crystal contracts, it draws new ink into the head ready for use on the next pass of the head. This process, like the thermal process, happens within less than 1 microsecond.

There isn’t really a clear winner on which process is better. While heating the ink in the thermal process sounds like a bad idea, the ink has been designed for this and leaves no damaging effect on the ink.

The dots of ink that are sprayed onto the paper are normally around 1 to 20 microns in diameter. To produce different tones and varying intensities of colour, these dots of ink have to be placed onto the paper precisely. The printer does this in two ways.

First, the printer uses a disk-like sensor to advance the paper. This makes sure that the ink does not overlap and cause banding. This works along with a nozzle pitch sensor located on the printer itself. The nozzle pitch sensor controls the spacing between the dots of ink and, along with the paper, the advanced sensor is designed to achieve the highest DPI settings.

The movement of the printer's head is controlled by what looks like a plastic strip called a ‘code strip’ or ‘timing strip’. You have probably seen this strip sitting in your printer at the back inside the printer. The strip looks as though it is solid grey, though in fact is a set of microscopic lines which the carriage reads through the use of a photodetector.

You may have had problems with your printer not printing in the correct place, or have an error code of a paper jam in the past. If you have this problem it is always worth checking the code strip and giving it a clean as this can really help your printing quality.

Now that we’ve discussed the mechanical side of the printer, we will take a look at the journey the image file takes as it goes through the printing process once you have clicked print:

- Once we have clicked ‘print’, the editing software sends the image data to the printer driver.

- The printer driver translates the image into data that the printer can understand and the head can use to spray the ink.

- Once the data is converted, it is sent over the printer and can be stored in the printer's own memory or RAM.

- This is when the printing process begins and the paper is drawn into the printer. By using the page data the advanced paper sensor is able to advance the paper precisely to the point that ink needs to start being sprayed at.

- The data is also fed to the photo-sensor on the head which will use the coding strip to know when to spray the ink.

- The data will be sent to the head in order for it to know which colours to print and where.

- Once everything has come together the print is made.

This process of sending and converting the data takes a matter of seconds, and the print is usually made within two to five minutes.

That’s just a brief overview of how an inkjet printer works. Luckily, thanks to the process, as well as good colour management and workflow, we can seamlessly click print and receive stunning results.

To shop for Fotospeed’s inkjet printers, and variety of other printers, click here.

You can also watch our YouTube video on how inkjet printers work.

|

Want to learn more about printing or photography? Sign up to our newsletter for the latest insights from the experts at Fotospeed!

You can also check out some of our other blogs for more tips and tricks.

|

|